Interconnection for Industry 4.0

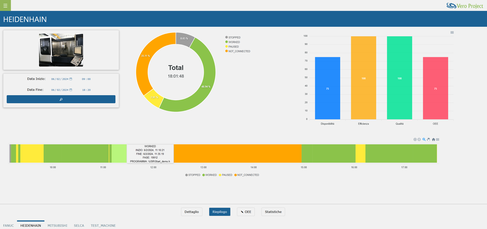

QuickMONITOR developed by Vero Project is the application that allows automatic monitoring and collection of hours from over 20 different CNCs, the most popular on the market: Heidenhain, Fanuc, Siemens, Selca, Mitsubishi, Makino... etc.

It is possible to know the status of the machine, the most important machining parameters and collect the machining hours by querying the CNC without human intervention as required by the Industry 4.0 standard.

QuickMONITOR allows the interconnection between machine tools numeric control end the company’s ERP. The connection is totally software and doesn’t require any kind of hardware installation on the machine.

QuickMONITOR monitors the work in progress and the status of the machine in real timeoffering the possibility of access machine data from any company’s pc. In the event of alarms from the machine, the system automatically sends a warning email with the type of problem reported.

• Automatic hours collecting for each working task

• Job order and working task

• Machine status, on/off

• Spindle in operation

• Progress

• Spindle absorption

• Which tool in use

• Part Program in use

QuickMONITOR records actual processing data by recording the job order and the processing phase directly from the part-program. The actual cutting hours are thus collected and sent to external applications or directly to  allowing a constant verification of the processes and the relative production plan in perfect harmony with the with the "Industry 4.0 Interconnection" regulation.

allowing a constant verification of the processes and the relative production plan in perfect harmony with the with the "Industry 4.0 Interconnection" regulation.

CONTACTS

To enquire about Industry 4.0 solutions please fill in the form

Note: Fields with an asterisk are required